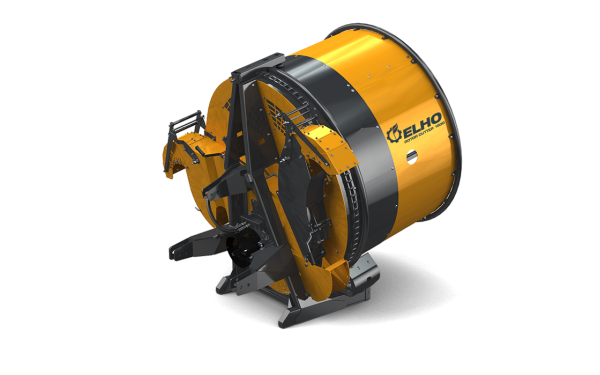

RotorCutter 1500

Description

The ELHO RotorCutter 1500 for effective forage/straw distribution and shredding!

With the ELHO RotorCutter 1500, forage can be distributed on the feeding table and the work carried out easily with one tractor. The RotorCutter 1500 is also ideal for shredding and spreading straw bales, also in deep boxes. This machine has many uses, and plenty of additional equipment is available for various working conditions and needs.

The RotorCutter 1500 is especially designed for shredding straw and forage bales. The length of the chaff can be adjusted. Forage and straw can be spread in both directions, both right and left. The strong loading fork makes the work easier and faster.

The RotorCutter 1500 can also be trailed. A wheel and drawbar set is available as additional equipment along with many more useful accessories.

The RotorCutter 1500 is a durable and affordable option for forage and straw distribution.

Addons

Additional cylinder for loading

Flow regulator valve kit

Rubber extension for chute

Hydraulic control of spout height, right

Hydraulic control of spout height, left

Hydraulic controlled swivel spout

Retrofit wheel kit